Welcome to Reardon Metals

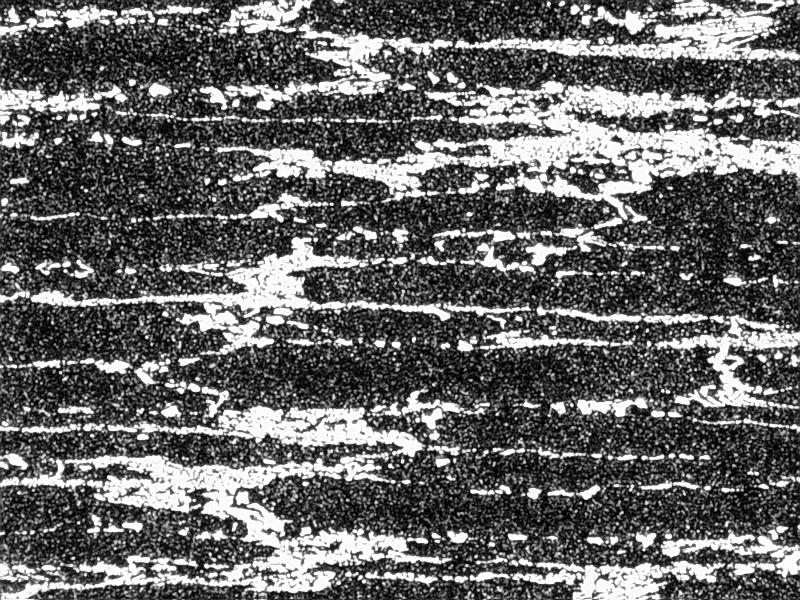

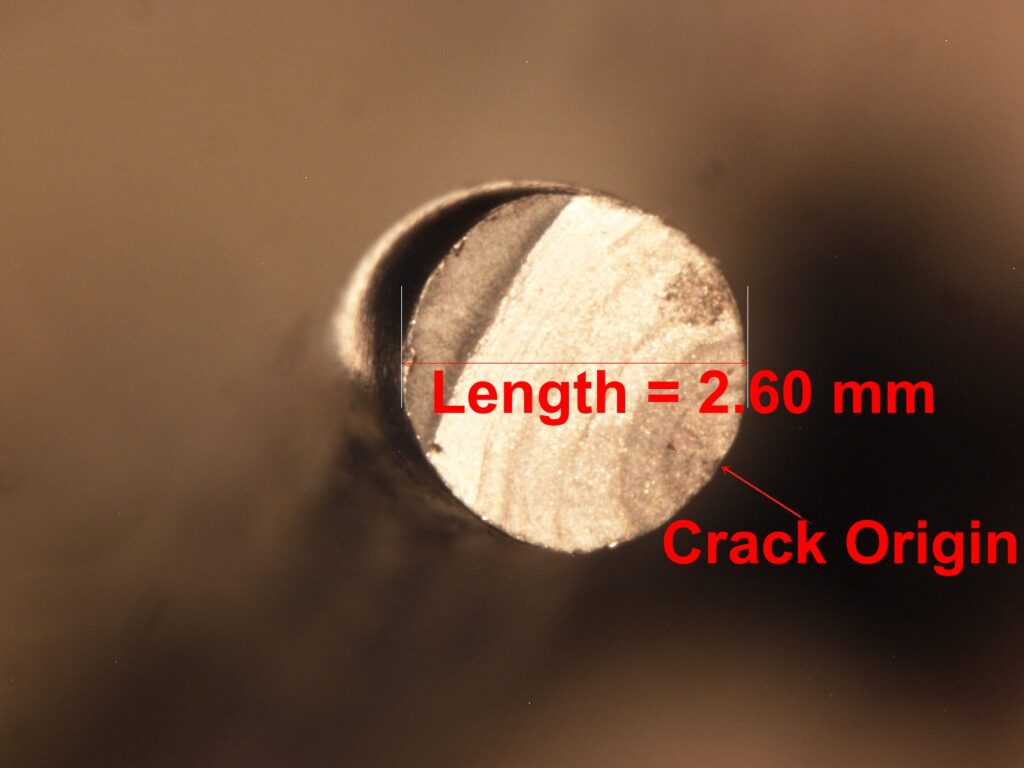

Reardon Metals offers full-spectrum consulting services for technical engineering projects from research and development to design, process engineering, testing and fabrication, production scale-up, and failure analysis. Reardon Metals has recently invented an entire new family of super high speed steel alloys, and US patent 12,234,536 B2 entitled High Speed Steel Composition was granted on February 25th, 2025 as a result. You can read more about them on our Steel Alloy Products page. In addition to inventing new steel alloys, Reardon Metals provides heat treat consulting, materials and process engineering, mechanical engineering, root cause analysis, metallurgical services and training to industrial corporations worldwide. Nitriding and case carburizing in both controlled atmosphere furnaces and vacuum furnaces is a specialty, as is failure analysis and microstructural analysis of industrial, medical and aerospace components and automotive gearing. Our expertise in industrial heat treating operations and processes includes press quenching of automotive and aerospace gearing and industrial bearing races as well as tempering, annealing and normalizing processes.

Click on the images below to enlarge them.